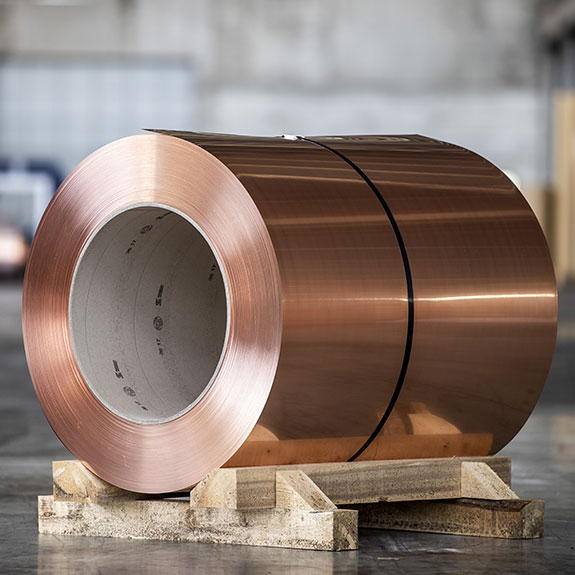

Copper strips, sheets and laminates for building and industrial applications.

Silmet, a traditional copper tube manufacturer, has started manufacturing copper strip, sheet and laminate for building and industrial applications.

In line with its long tradition, Silmet has always invested in the very best and most advanced technologies available for this kind of product using state-of-the-art equipment.

Characteristics

Copper is used to produce the whole Silmet product range. Copper has many advantages over other materials including excellent electrical and thermal conductivity, unparalleled mechanical and physical properties, not to mention the fact that it is 100% recyclable.

The production and finishing lines, which are largely automated, guarantee the top quality standards of the products present on the market.

Silmet’s copper strips, sheets and laminates are ideal for use in the construction industry, in particular for roofing and cladding. The copper strip can be used to make gutters, downpipes, cladding and roofing systems. In the industrial field Silmet copper strip meets the strictest quality standards set out in EN 1172, especially in regard to annealing, dimensional tolerance and coil weights.

Due to copper’s excellent corrosion resistance, all strip supplied does not require any coating, such as painting or varnish, or special maintenance, and is highly resistant to corrosion, not to mention the purely cosmetic aspect which copper confers to the products it is made with.

Directives

The international standards to which Silmet strips conform are:

EN 1172

Sheet and strip for building purposes

EN 1652

Plate, sheet, strip and circles for general purposes

According to Specification

Products with marks, dimensional tolerances, physical states and other characteristics defined on specific request by the Customer, even in partial modification of the specifications indicated above.

Supply Conditions

Raw material:

Cu-DHP (Cu 99,9% min. - P da 0,015% a 0,040%)

Cu-ETP (Cu 99,9% min. - Bi max. 0,0005% - O max. 0,040%1 - Pb max. 0,005%)

1 An oxygen content up to 0.060% is allowed, by agreement between the buyer and the supplier.

| Maximum width | 1 250 mm |

| Thickness | 0,10 mm a 2,5 mm |

| Inner diameter | 150 mm - 400 mm - 500 mm |

| Weight of coil | up to 12.000 kg |

Technical sheets

| designations | nominal thickness | tensile strength | 0,2% proof strength | elongation | hardness | ||||||

| Rm | Rp0,2 | A 60mm thickness up to 2,5 mm including | A thickness over 2,5 mm | ||||||||

| materiale | stato metallurgico | mm | N/mm2 | N/mm2 | % | % | HV | ||||

| symbol | number | from | up to and including | min | max | min | max | min | max | ||

| Cu-ETP Cu-DHP | CW004A CW024A | R200 | over 5 | 200 | 250 | (max 100) | - | 42 | - | - | |

| H040 | - | - | - | - | - | 40 | 65 | ||||

| R220 | 0,2 | 5 | 220 | 260 | (max 140) | 33 | 42 | - | - | ||

| H040 | - | - | - | - | - | 40 | 65 | ||||

| R240 | 0,2 | 15 | 240 | 300 | (min 180) | 8 | 15 | - | - | ||

| H065 | - | - | - | - | - | 65 | 95 | ||||

| R290 | 0,2 | 15 | 290 | 360 | (min 250) | 4 | 6 | - | - | ||

| H090 | - | - | - | - | - | 90 | 110 | ||||

| R360 | 0,2 | 2 | 360 | - | (min 320) | 2 | - | - | - | ||

| H110 | - | - | - | - | - | 110 | - | ||||

The values in parentheses are not standard requirements, but are given for information only.

| nominal thickness – mm | thickness tolerances for nominal widths – mm | ||||

| over | up to and including | up to and including 350 | over 350 up to and including 700 | over 700 up to and including 1.000 | over 1.000 up to and including 1.250 |

| 0,1 (included) | 0,2 | ± 0,018 | - | - | - |

| 0,2 | 0,3 | ± 0,022 | ± 0,03 | ± 0,04 | - |

| 0,3 | 0,4 | ± 0,025 | ± 0,04 | ± 0,05 | ± 0,07 |

| 0,4 | 0,5 | ± 0,030 | ± 0,05 | ± 0,06 | ± 0,08 |

| 0,5 | 0,8 | ± 0,040 | ± 0,06 | ± 0,07 | ± 0,09 |

| 0,8 | 1,2 | ± 0,050 | ± 0,07 | ± 0,09 | ± 0,10 |

| 1,2 | 1,8 | ± 0,060 | ± 0,08 | ± 0,10 | ± 0,11 |

| 1,8 | 2,5 | ± 0,070 | ± 0,09 | ± 0,11 | ± 0,13 |

| nominal thickness – mm | width tolerances for nominal width – mm | |||||||

| over | up to and including | up to and including 50 | over 50 up to and including 100 | over 100 up to and including 200 | over 200 up to and including 350 | over 350 up to and including 500 | over 500 up to and including 700 | over 700 up to and including 1.250 |

| 0,1 (including) | 1 | + 0,20 | + 0,30 | + 0,40 | + 0,60 | + 1,00 | + 1,50 | + 2,00 |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| 1 | 2 | + 0,30 | + 0,40 | + 0,50 | + 1,00 | + 1,20 | + 1,50 | + 2,00 |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| 2 | 2,5 | + 0,50 | + 0,60 | + 0,70 | + 1,20 | + 1,50 | + 2,00 | + 2,50 |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| nominal thickness – mm | width tolerances for nominal width – mm | ||

| over | up to and including | up to and including 350 | over 350 up to and including 1.250 |

| - | 2 | + 2 | + 6 |

| 0 | 0 | ||

| 2 | 5 | + 4 | + 8 |

| 0 | 0 | ||

| designation | tensile strength | 0,2% proof strength | elongation | hardness | |||||

| material | material condition | N/mm2 | N/mm2 | % | HV | ||||

| symbol | number | min | max | min | max | min | min | max | |

| Cu-DHP | CW024A | R220 | 220 | 260 | - | 140 | 33 | - | - |

| H040 | - | - | - | - | - | 40 | 65 | ||

| R240 | 240 | 300 | 140 | - | 8 | - | - | ||

| H065 | - | - | - | - | - | 65 | 95 | ||

| R290 | 290 | - | 250 | - | - | - | - | ||

| H090 | - | - | - | - | - | 90 | - | ||

| nominal dimensions | tollerances | |||||

| mm | mm | |||||

| thickness | width up to and including | preferred length | coil inside diameter | thickness | width | length of sheet |

| da 0,4 a 1 | 1.250 | 2.000 o 3.000 | 300, 400, 500 o 600 | ± 0,02 | + 2 0 | + 10 0 |

| 0,5 | ||||||

| 0,6 | ||||||

| 0,7 | ||||||

| 0,8 | ||||||

| 1 | ||||||